Choosing and Using Bandsaw Blades 1

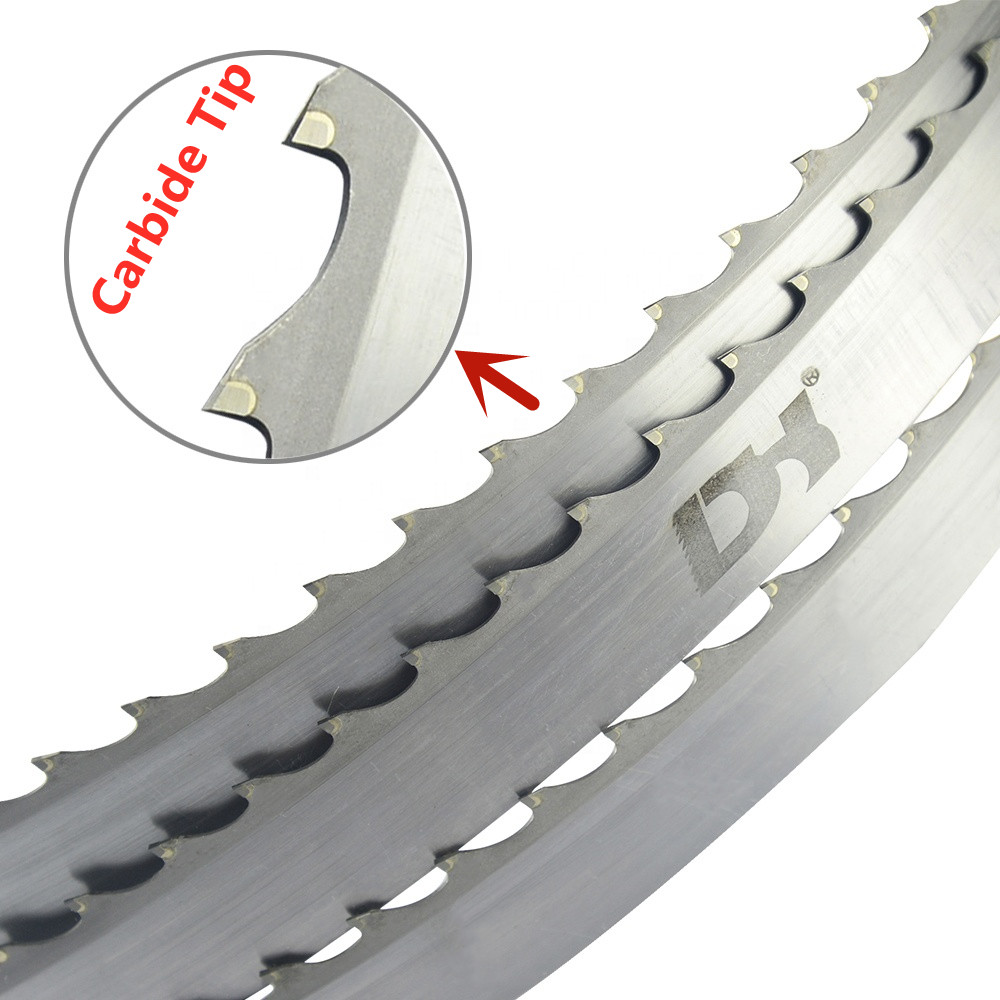

Bandsaw blades come in a variety of width, tooth shapes, materials, and configurations. DH Cutter has a great selection. Click then to start shopping now. Or keep reading to learn further about how to choose and use bandsaw blades.

CHOOSING BANDSAW BLADES

Bandsaw Blade width

We use the word “width” but really it comes down to two different points: The maximum capacity your bandsaw can accommodate and the minimal radius you want to cut. Start by consulting the manufacturer’s instructions.

First, to do re-sawing, cant or cut-off sawing, use your bandsaw’s maximum blade width. This will keep the cuts nice and straight and you’ll get a stable and nice feed rate without breaking blades.

On the other end of the scale, if you do contour sawing, use a blade that's narrow enough to cut the expected radius. The map below shows the correlation between blade range and the minimal radius it'll cut.

|

Blade Range ( Elevation) |

Minimum Radius (Inches) |

|

1/8 |

3/16 |

|

3/16 |

5/16 |

|

1/4 |

5/8 |

|

3/8 |

1-1/2 |

|

1/2 |

2-1/2 |

|

5/8 |

4 |

|

3/4 |

5-1/2 |

|

1 |

7 |

Bandsaw Blade Thickness

Choosing the appropriate thickness of the blade is important. Continual flexing and heating and cooling causes metal fatigue and eventually, failure.

The thickness of the blade depends on the periphery of the wheel, and the work to be done. Thick blades withstand further cutting strain from straight cuts but can break more frequently from the bending and twisting action. Thinner blades perform well for lighter work. The following chart shows ideal blade thickness for different wheel periphery.

|

Wheel Periphery ( Inches) |

Blade Thickness ( Inches) |

|

4-6 |

0.014 |

|

6-8 |

0.018 |

|

8-10 |

0.020 |

|

11-18 |

0.025 |

|

18-24 |

0.032 |

|

24-30 |

0.035 |

|

30+ |

0.042,0.050,0.063 |

Teeth number of band saw blade

In determining teeth per inch (TPI), try to find a balance finish and feed rate. Blades with more teeth cut slower and smoother. Blades with less teeth cut faster, with slightly rougher finish.

For any kind of perfection processing, the rule of thumb is to always try to keep at least three teeth in the material at all times. This adds stability and delicacy and applies to cutting in both metal and wood.

Use coarse tooth blades (2 or 3 TPI) for re-sawing and cutting thicker things. For general wood cutting duties in typical 3/4” material, use a 4 TPI blade for coarse, fast processing and a 14 TPI blade for slower, smoother processing. A blade in the 6 to 8 TPI range provides good general- purpose performance. This same equation applies whether you’re cutting wood or metal. For thinner metals and plastics under 1/4” use an indeed finer blade (18–32 TPI).

Bandsaw Blade Tooth Styles and Sets

There are three tooth styles in bandsaw blades: regular, skip and hook.

Regular tooth blades have proportionally spaced teeth and are immaculately suited for general- purpose slice and figure sawing. Regular blades are ideal for cutting thin materials with a fine finish.

Skip tooth blades have extensively spaced teeth at a 0 degree rake angle to help preventing clogging when cutting soft wood,non-ferrous metal and plastics.

Hook tooth blades have a deeper gullet — that is, larger teeth — and a positive 10 degree rake angle. This helps the blade to feed into the material more aggressively. The result is faster cutting rates. Hook tooth blades are generally used for long cuts in thicker wood, hardwood, plastic and metal.

Variable Pitch blades have interspersing sets of different sized teeth to give a fast cut with a smooth finish, ideal for joinery and slice angles.

You can see a blade’s set by looking down on the teeth.

A raker tooth set has one tooth going to the leftism, one to the right, followed by a straight, or unset, tooth, which is called a raker.

An alternate tooth set has one tooth going left, one going right, also left, right, etc. There's no raker tooth. The double alternate plus raker has an unset raker tooth following two left-right combinations.

A wavy tooth set has groups of teeth set left and right, separated by unset raker teeth. Wavy set blades are made primarily with the small teeth recommended for cutting thinner metal sections, tubes, pipes, thin sheets,etc.

To be countinued...